- your*skype

- CHINE

- In stock

- 20MVC-18

This is a powerful product, first-class quality, long service life, product has a variety of styles, a variety of colors, a variety of sizes.

Cross Colours Camo Print Tank half mengo details

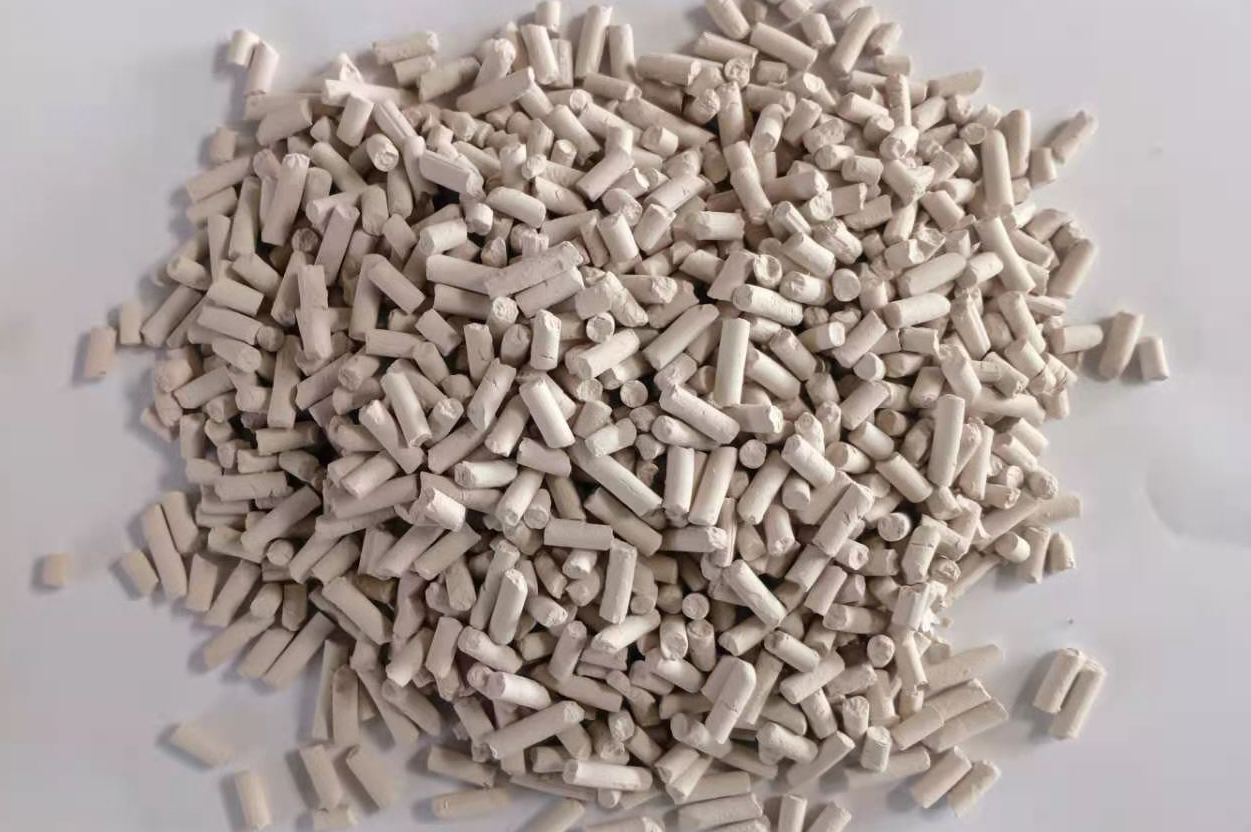

Nano aerogel flexible thermal insulation blanket is a new type of environmental friendly inorganic thermal insulation material that is flexible, hydrophobic, stable at high temperature, has no attenuation of thermal insulation effect over time, and is fire retardant.

This insulation felt has an ultra-low thermal conductivity coefficient, with a thickness 75% thinner than traditional insulation materials, meeting the construction requirements of insulation projects in narrow spaces and high insulation requirements. The overall performance of the structure is stable, not afraid of rough construction, and installation is faster and easier, shortening the construction cycle and saving daily maintenance costs.

This insulation felt is suitable for high and low temperature working environments, and the working temperature of universal products can reach 650 ℃ (1202 ℉), with a minimum of -200 ℃ (-328 ℉). The working temperature of special products can reach 1100 ℃ (2012 ℉).

Application characteristics

Superior thermal insulation performance: The thermal insulation performance is 3-8 times that of traditional materials. To achieve the same insulation effect, the required insulation layer thickness is only 1/2 to 1/5 of traditional materials, and the service life is long.

Good mechanical properties: lightweight, flexible, and excellent tensile strength.

Fire resistance and hydrophobicity: The fire resistance performance is A1 level, with a hydrophobicity rate of ≥ 99%, and it isolates liquid water.

Easy to process, convenient for construction, and space saving: ordinary cutting tools can be used to process into shapes suitable for complex components. Low thickness insulation layer saves a lot of space, greatly shortens working hours, and greatly reduces labor demand.

Saving logistics costs: A thinner insulation layer significantly reduces logistics costs compared to traditional materials.

application area

Oil extraction steam pipeline

Prefabricated insulation pipes for thermal power plants and chemical plants

Insulation of various storage tanks, high and low temperature kilns, containers and other equipment

Mobile lifebuoy, shelter, and hull insulation

Thermal insulation of high-speed trains, subways, and other vehicle bodies in transportation

Insulation of interior and exterior walls of buildings

Special performance

Good insulation and thermal insulation effect, with obvious energy-saving effect; A-level fire prevention, overall hydrophobic, and maximum avoidance of CUI (corrosion); The service life can reach up to 20 years and can be reused multiple times; The entire transportation and construction process is environmentally friendly and does not shed dust.