- your*skype

- CHINE

- In stock

- 20MVC-18

This is a powerful product, first-class quality, long service life, product has a variety of styles, a variety of colors, a variety of sizes.

Cross Colours Camo Print Tank half mengo details

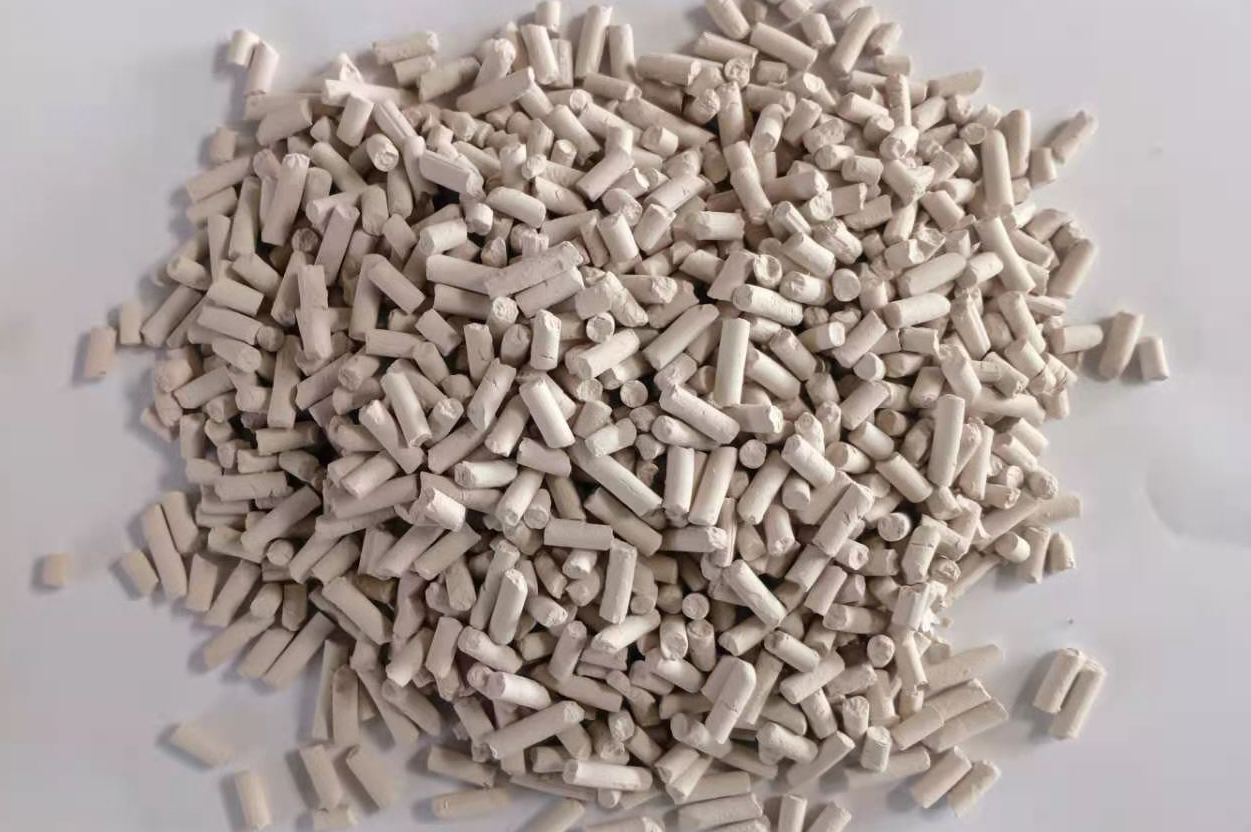

Saturated hydrogenation catalyst

(1) Dry gas saturation hydrogenation catalyst

This catalyst is used for coking dry gas and catalytic dry gas saturation hydrogenation. Coking dry gas and catalytic dry gas are excellent raw materials for hydrogen production, but the impurities such as olefins and sulfur contained in them are toxic substances of hydrogen production catalysts and must be pretreated. Saturation hydrogenation can saturate the olefins in coking dry gas and catalytic dry gas into alkanes, hydrogenate non hydrogen sulfide sulfides into hydrogen sulfide, and then further remove them through zinc oxide.

Used for the saturation hydrogenation of dry gas generated in the C4 aromatization unit, where olefins are saturated and hydrogenated into alkanes, which can be used as feedstocks for ethylene cracking.

(2) Carbon trisaturated hydrogenation catalyst

This technology and catalyst are used for saturation hydrogenation of carbon three fractions. The propane dehydrogenation unit has strict regulations on the raw materials. By saturation hydrogenation, the olefins can be saturated into alkanes, and non hydrogen sulfide sulfides can be hydrogenated into hydrogen sulfide. Then, it is further removed by zinc oxide to meet the specifications required by the dehydrogenation unit. In addition, by saturating the olefins into alkanes through hydrogenation, they can be used as feedstocks for ethylene cracking.

3) Carbon four saturated hydrogenation catalyst

This technology and catalyst are mainly used in the following process:

a. Used for producing high-purity n-butane and isobutane. High purity C4 alkanes are environmentally friendly refrigerants and solvents for polyolefin catalysts.

b. Used for producing ethylene cracking raw materials. After hydrogenation of normal olefins in mixed C4 to n-butane, it is used as a raw material for ethylene cracking, and the yield of ethylene cracking by n-butane can reach 50%.

c. Raw materials used for the production of maleic anhydride. After hydrogenation of normal olefins in mixed C4 to n-butane, it can be used as a raw material for producing maleic anhydride.

d. Raw materials used for producing isobutane dehydrogenation. The isobutane dehydrogenation process requires the olefin content in the raw material to be less than 1%, therefore, it is necessary to saturate the raw material for hydrogenation.

4) C5 saturated hydrogenation catalyst

This technology and catalyst are used for saturation hydrogenation of C5 fractions produced in ethylene cracking units. The C5 fraction produced by the ethylene cracking unit separates isoprene, isoprene, and cyclopentadiene, and the remaining components undergo saturation hydrogenation to hydrogenate olefins into alkanes, which are then returned to the cracking unit as cracking raw materials or used as foaming agents.